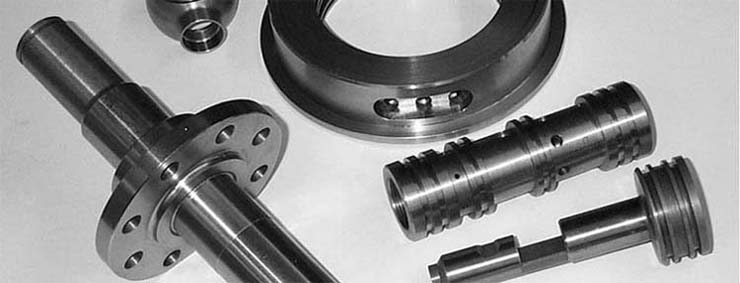

Precision Machining

What is CNC Machining?

CNC machining technology was developed in the United States in the 1950's for the US Air Force by metalworking machine tool builders. The invention of the CNC was a major advance in the ability of machines to faithfully reproduce complex part machining steps more accurately without human intervention or variability.

CNC stands for Computer Numerically Controlled. CNC always refers to how a machine operates, that is, its basic method of controlling movement. Put another way, a CNC machine uses a stream of digital information (code) from a computer to move motors and other positioning systems in order to guide a spindle over raw material.

A CNC machine uses mathematics and coordinate systems to understand and process information about what to move, to where, and how fast. Most CNC machines are able to move in three controlled directions at once. These directions are called axes (pronounced ax-ees). The axes are given simple names such as X, Y and Z (based on the Cartesian Coordinate System). The X axis is always the longest distance a machine or a part of a machine must travel. X may be the movement from front to back, Y the movement from left to right, and the Z is almost always vertical movement (normally the spindle's positioning movement up and down).

A CNC machine must be able to communicate with itself to operate. A computer numeric control unit sends position commands to motors. The motors must talk back to the control that, indeed, they have acted correctly to move the machine a given distance. The ability of CNC machines to move in three (or more) directions at once allows them to create almost any desired pattern or shape. All of this processing happens very fast.

Fokli Presicion CNC Machining

Fokli Precision Mfg Co., Ltd. was separated from Fokli Castparts in 2008 for enlarge the capacities and provide better services for the group and other customers, by December 2012, machining factory area: 6000m2; employees: 220; precision wire-cut machines imported from Germany and other countries: 15; electrical discharge machines imported from Germany and other countries: 25; deep-hole dischargers: 5; machining centers: 25; surface grinders: 15; tool grinders: 10; NC turn-milling equipment: 33; and welders: 3. Diverse advanced measuring instruments such as three-coordinate measuring machines: 2; vision measuring instruments: 2; roundness measuring instrument: 1.

The machining products of the company, boasting reasonable price and top quality, are widely used in the fields of precise machinery, transportation and medical apparatus, etc. The company is constantly implementing the quality control systems of ISO9000, TS16949 and 6S on site, it strives to become a world renowned company.

Sand Casting

Sand Casting Brake Disc Series

Brake Disc Series Brake Drum Series

Brake Drum Series Differential Cases

Differential Cases Featured Cases

Featured Cases Investment Casting

Investment Casting Cylinder End Mounts

Cylinder End Mounts Shaft Coupling

Shaft Coupling Cast Steel cable Protector

Cast Steel cable Protector Home Hardware Accessories

Home Hardware Accessories Featured Cases

Featured Cases Precision Machining

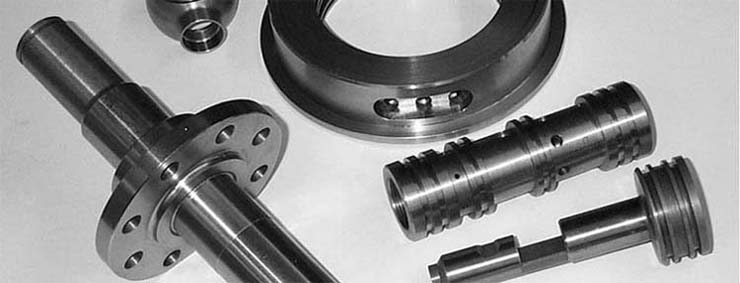

Precision Machining Hydraulic Piston

Hydraulic Piston Flange

Flange Featured Cases

Featured Cases Precision Stamping

Precision Stamping Featured Cases

Featured Cases Precision Forging

Precision Forging Featured Cases

Featured Cases Die Casting

Die Casting Featured Cases

Featured Cases Gravity casting

Gravity casting Featured Cases

Featured Cases Cold Forming

Cold Forming Featured Cases

Featured Cases Magnetic Assemblies

Magnetic Assemblies NdFeB Magnets

NdFeB Magnets Engineered Assemblies

Engineered Assemblies Magnetic Separators

Magnetic Separators Attraction Kits

Attraction Kits Powder Metal and Sintered Part

Powder Metal and Sintered Part Fokli Sourcing

Fokli Sourcing